StellarTune EQ8/EQ8-R Mount

(Stated price is for upgrade/tune to customers own mount)

Please place your order and pay via the website to book your mount in or call us - 02392 570283 - dave@darkframe.co.uk - to arrange a date/time if you want to bring the mount to us.

To see what we do to improve the existing Sky-Watcher EQ Range, please visit our customer Testimonials Page...

NEQ6 Performance:

Upgrading the worm gear bearings to Hybrid-ceramic items and belt-driving the motors substantially reduces backlash and improves periodic error. Tuned mounts run typically at circa 3 arcseconds RMS, and can be autoguided to consistently perform sub-arcsecond tracking, especially when allied to a QHY Polemaster.

We have HEQ5, NEQ6, AZEQ6GT and now EQ8 Reference mounts that are utilised to constantly improve our tuning methodology and demonstrate the benefits of enhancing the mount.

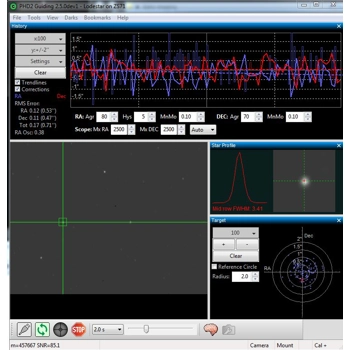

Here is a customer supplied PHD graph of one of our EQ6 Mounts. Other customer supplied examples are available upon request.

Image: 2015 (1st generation) hypertuned NEQ6 5.86arcsecs RMS with standard SKF bearings

Work includes:

Each EQ Mount is examined externally for any damage and owners are notified for any extra-parts (replacement Sky-Watcher EQ bolts, for example) if needed. We photograph dis-assembly and reassembly of key components, and video before and after with a sound check that creates a unique sound signature for each mount (for internal use ony).

The Mount is stripped back in both axis to component level, inspected for damage or wear, and degreased. Owners are notified if any extra-parts are required or upgraded by request.

Cone Axis bearings are degreased, checked for wear and ultrasonically cleaned and re-lubricated, as are the bearing cone surfaces checked and cleaned in the mount.

All external threaded bolts on mount and tripod (if supplied) are degreased, ultrasonically cleaned and re-lubricated.

Motors tested and gearboxes checked* (*where applicable).

Mount is reassembled using upgraded greases and oils which operate in all temperatures from -25ºC to +50ºC (we use them in our Export Service and our own products so have been tested at these temperatures!).

The Mount is then bench tested and adjusted to remove backlash and to ensure operation of mount.

GoTo Handset and Mount is checked for Firmware updates and updated with latest code as required and tested for operation.

Free fitting of QHY Polemaster adapter if purchased and camera test to ensure correct focus and operation.

In the case of axis repairs and tuning we carry out a load test on every mount with either an 8 inch reflector or 100mm f9 refractor - or 70mm refractor for smaller mounts, and adjust worm back lash to dial out as much movement a possible so to ensure the mount is performing as it should under real-world conditions.

All work carried out is covered by our 2 Year limited Mechanical Warranty.

GBP

GBP AED

AED AFN

AFN ALL

ALL AMD

AMD ANG

ANG AOA

AOA ARS

ARS AUD

AUD AWG

AWG AZN

AZN BAM

BAM BBD

BBD BDT

BDT BGN

BGN BHD

BHD BIF

BIF BMD

BMD BND

BND BOB

BOB BRL

BRL BSD

BSD BTN

BTN BWP

BWP BYN

BYN BYR

BYR BZD

BZD CAD

CAD CDF

CDF CHF

CHF CLF

CLF CLP

CLP CNH

CNH CNY

CNY COP

COP CRC

CRC CUC

CUC CUP

CUP CVE

CVE CZK

CZK DJF

DJF DKK

DKK DOP

DOP DZD

DZD EGP

EGP ERN

ERN ETB

ETB EUR

EUR FJD

FJD FKP

FKP GEL

GEL GGP

GGP GHS

GHS GIP

GIP GMD

GMD GNF

GNF GTQ

GTQ GYD

GYD HKD

HKD HNL

HNL HRK

HRK HTG

HTG HUF

HUF IDR

IDR ILS

ILS IMP

IMP INR

INR IQD

IQD IRR

IRR ISK

ISK JEP

JEP JMD

JMD JOD

JOD JPY

JPY KES

KES KGS

KGS KHR

KHR KMF

KMF KPW

KPW KRW

KRW KWD

KWD KYD

KYD KZT

KZT LAK

LAK LBP

LBP LKR

LKR LRD

LRD LSL

LSL LYD

LYD MAD

MAD MDL

MDL MGA

MGA MKD

MKD MMK

MMK MNT

MNT MOP

MOP MRO

MRO MRU

MRU MUR

MUR MVR

MVR MWK

MWK MXN

MXN MYR

MYR MZN

MZN NAD

NAD NGN

NGN NIO

NIO NOK

NOK NPR

NPR NZD

NZD OMR

OMR PAB

PAB PEN

PEN PGK

PGK PHP

PHP PKR

PKR PLN

PLN PYG

PYG QAR

QAR RON

RON RSD

RSD RUB

RUB RWF

RWF SAR

SAR SBD

SBD SCR

SCR SDG

SDG SEK

SEK SGD

SGD SHP

SHP SLL

SLL SOS

SOS SRD

SRD SSP

SSP STD

STD STN

STN SVC

SVC SYP

SYP SZL

SZL THB

THB TJS

TJS TMT

TMT TND

TND TOP

TOP TRY

TRY TTD

TTD TWD

TWD TZS

TZS UAH

UAH UGX

UGX USD

USD UYU

UYU UZS

UZS VES

VES VND

VND VUV

VUV WST

WST XAF

XAF XCD

XCD XOF

XOF XPF

XPF YER

YER ZAR

ZAR ZMW

ZMW ZWL

ZWL UK English

UK English Swedish

Swedish Spanish

Spanish Norwegian

Norwegian Dutch

Dutch German

German Arabic

Arabic